How to make a giant gummy bear?

Soft candy is a kind of soft, elastic and tough functional candy. It is mainly made of gelatin, syrup and other raw materials. After multiple processes, it forms a fine and durable solid candy with different shapes, textures and flavors. It is elastic and chewy. Through modern technology, it is processed into a small package product that is convenient to carry and ready to eat. It is a good product for parties, leisure and travel.

With the progress of society and the improvement of people’s living standards, safe, hygienic and convenient food will become people’s first choice. Gummies can be regarded as a favorite food of men, women and children. They are soft, springy, and have a variety of flavors. So how is such a soft candy made?

How to make a giant gummy bear?

Process flow:

Adjusted starch milk—blending—boiled sugar—cooling—forming—packing

Detailed steps:

1. Adjusting starch milk: To make soft sweets, half of sweet potato starch and corn starch can be used. Mix the starch, add the corresponding ingredients, stir evenly, and heat over a slow heat.

2. Pulp: Use boiling water about 17 kilograms to pour into the prepared starch milk, mature the starch milk into a slurry, stir quickly, stir until there are no lumps, and heat the sugar that has been heated to boiling, completely melted and filtered. Add the mixture with starch syrup in three batches to the well-mixed paste, and stir while adding. After stirring, the sugar can be boiled.

3. Boil the sugar: Put the prepared and stirred syrup on the fire and boil the sugar. Stir while boiling, it takes about an hour. The temperature of the pot is 115-120 degrees Celsius; it can be lower in winter and higher in summer. After removing the heat, add the spices and stir well.

4. Cooling: There are two cooling methods. One is to spread a layer of starch on the iron plate to prevent the sugar dough from sticking to the iron plate; the other is to rub some vegetable oil on the iron plate as a lubricant. .

5. Forming and packaging: When the sugar billet is cooled to moderate hardness on the iron plate, it can be divided into pieces and pressed into pieces. When it continues to be cooled to the appropriate hardness required for forming, it can be cut into pieces by a cutting machine. After being formed, after a little cooling, the starch granules adhering to the surface of the sugar block can be removed by a powder remover. The glutinous rice paper is used as the lining, and the label paper is wrapped to make the kinks tight.

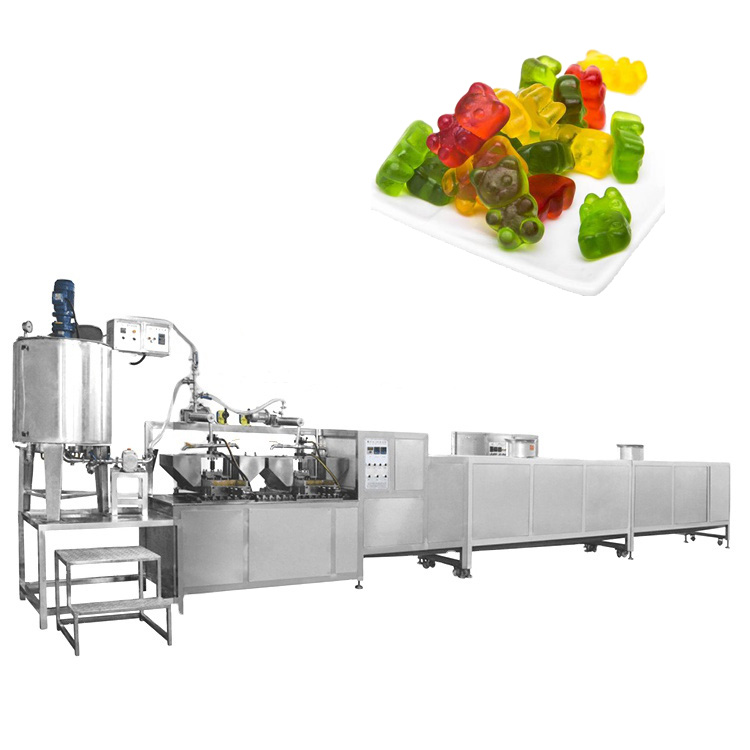

Soft candy is a kind of soft and elastic candy. In the production process of industrial soft candy, gummy machine is often used to cast it, which can greatly increase the production efficiency of soft candy. Soft candy machine is mainly used for making soft candy. The ingredients are processed so that the ingredients are mixed and reacted, and then poured into the candy model from the inside of the tank in time for cooling, to complete the production of soft candy.

The batching tank of the soft candy machine on the market has a large volume and is not easy to move. The scope of casting is limited, the working area is small, and the production efficiency needs to be improved. The uneven mixing of materials in the batching tank affects the quality and taste of the final formed candy. It is not easy to melt the ingredients in the ingredient tank, and the sugar boiling operation needs to be carried out separately. The process is complicated, the molding shape of the soft candy is not easy to change, and the variety is single. To this end, we propose a new type of gummy bear making machine.

The main features of the soft candy machine:

- The linear structure is simple and easy to install and maintain.

2. Pneumatic components, electrical components, and operating components all adopt world-leading brand-name components.

3. The high-pressure double crank controls the opening and closing of the mold, simple control and convenient operation.

4. The operation has a high degree of automation, a high degree of intelligence, and no pollution.

5. The connector is connected to the air conveyor, which can be directly connected in series with the filling machine.

The soft candy production line can choose electric heating or steam heating. The whole line adopts servo control and has higher stability. It is an ideal equipment for producing high-quality soft candy, saving manpower and saving space. You can choose single color, double color or multi-color, sandwich or no sandwich. According to your requirements, our engineers will design a unique production line for you.

We are a sales and service company that has established a complete production line of soft sweets, and one of China’s leading professional exporters, providing high-quality candy, chocolate, biscuits and packaging machinery for domestic and foreign customers. We not only provide advanced equipment with competitive and economic benefits, but also provide overall solutions for customers’ needs. If you have any needs in this regard, please feel free to contact us!